Industrial Oven Equipments for Heating Solutions

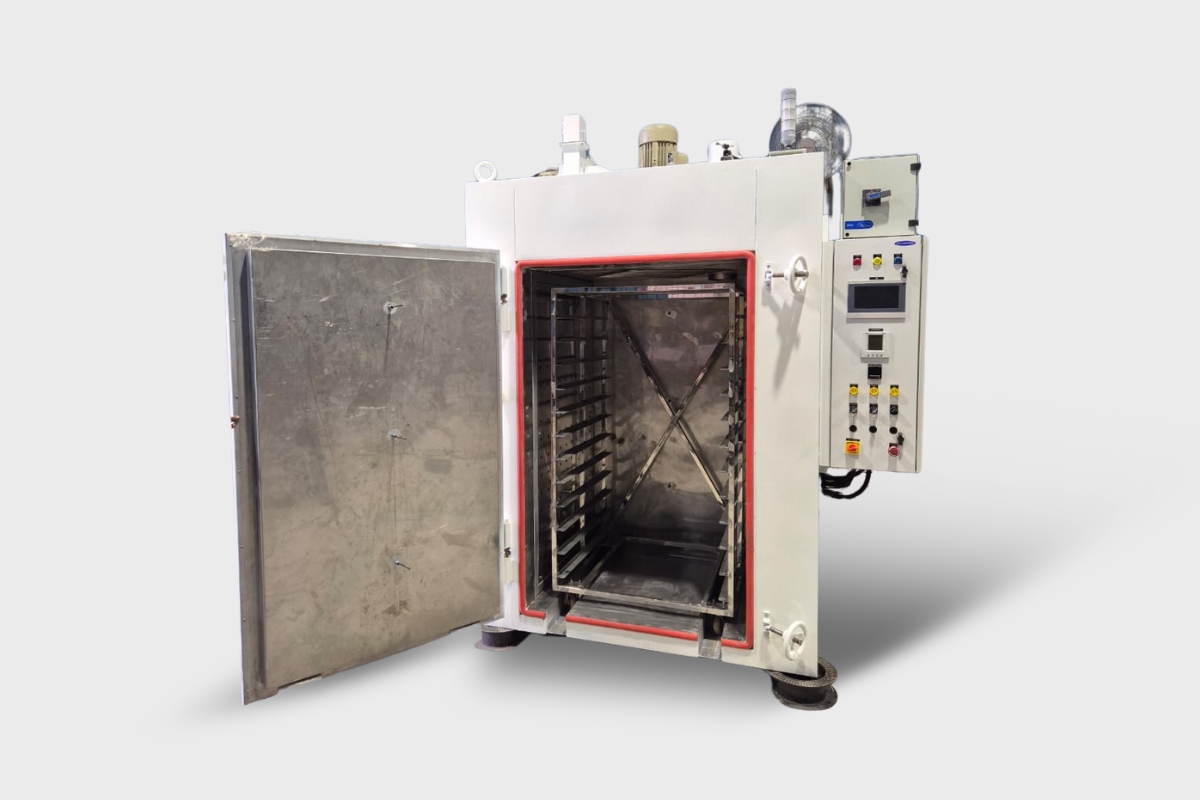

Oven Equipments

Key Features

Uniform Air Circulation

Forced-air convection with optimized airflow ensures even heating across all trays and racks.

Energy-Efficient Design

High-grade insulation and low heat loss chamber construction to reduce energy consumption.

Rugged Build Quality

Stainless steel inner chamber and powder-coated outer body for corrosion resistance and durability.

User-Friendly Interface

Easy-to-navigate control panel with safety alarms for over-temperature, door open, and system malfunction.

Applications

Drying Glassware

Chemical & Petrochemical

Automotive & Aerospace

Electronics Component

Construction Materials

Research Laboratories

Primary Benefits

Enhanced Product Quality

Reduced Downtime

Energy & Cost Efficiency

Faster Processing Time

Technical Specifications

| Product Name | Servo Hot Air Oven / Industrial Drying Oven |

| Construction | Outer: CRCA Steel (Powder-Coated), Inner: SS304 |

| Temperature Range | Ambient to 250°C |

| Temperature Accuracy | ±2°C |

| Capacity Options | 100L, 250L, 500L, 1000L |

| Heating Element | Nichrome wire with ceramic insulation |

| Air Circulation | Motorized Blower – Forced Convection |

| Insulation | Glass Wool (75mm thick) |

| Door Type | Front-opening with high-temperature gasket |

| Control Panel | Digital Temperature Controller with Timer |

| Power Supply | 230V (Single Phase) / 440V (Three Phase) |

| Safety Features | Overheat Cutoff, Door Interlock, Auto Shut-off |

| Applications | Drying, Curing, Sterilizing – Pharma, Labs, Electronics, etc. |

Why Choose Servo Enterprises for Oven Equipment?

Our Products

Batch Oven

A batch oven is a type of industrial oven designed for heating materials or products in batches, rather than continuously. They are typically used in manufacturing, processing, and research applications where controlled and consistent heat treatment is required.

Conveyor Oven

A conveyor oven uses a moving conveyor belt to transport items through a heated chamber. This allows for continuous, high-volume production and consistent heating of products, making it ideal for mass production in various industries

Curing Oven

A curing oven induces a chemical reaction in a material through heat, enhancing its strength and durability. This process, known as curing, is often used to solidify coatings, adhesives, and other materials by promoting cross-linking or other chemical changes.

Canopy Oven

Canopy ovens are built with an overhead hood-like structure, offering optimal heat containment for drying and preheating tasks. Best suited for larger or irregular-shaped parts in large-scale manufacturing, making them suitable for paint shops and component assembly lines.

Vacuum Oven

A vacuum oven uses reduced pressure (a vacuum) and heat to dry materials which are prone to oxidation. By lowering the pressure inside the chamber, the boiling point is reduced, allowing for drying at lower temperatures and preventing oxidation

Annealing Oven

An annealing oven is made for the heat treatment process called annealing. This involves heating a material to a controlled temperature and then cooling it slowly to alter its physical properties, enhances ductility and improves overall structural performance.

IR Oven

An infrared oven uses infrared radiation to heat materials, rather than relying on convection or conduction heating like conventional ovens. This means it heats objects directly through infrared waves, leading to faster and more efficient heating.

Post Curing Oven

A post-curing oven is an industrial oven used to subject cured materials to elevated temperatures enhancing material strength, stability, and performance, typically after an initial cure, to improve their physical properties and remove residual by-products.

Pellet Flow Oven

Pellet Flow Ovens are designed to heat-treat bulk materials like granules or pellets in motion. Offering uniform temperature control, these ovens are vital for drying and processing polymers, resins, and plastic pellets.

Double Deck Oven

A double-deck oven is a type of commercial oven that features two separate baking compartments, or "decks," stacked on top of each other. This design allows for baking multiple items simultaneously or different items at different temperatures.

Sleeve Heating Oven

Sleeve Heating Ovens specialize in heating shrink sleeves or tubing uniformly for labeling or insulation applications. Precision-controlled heating ensures consistent shrinkage and adherence, widely used in packaging and cable manufacturing.

Single Chamber Double Trolley Oven

A Single Chamber Double Trolley Oven is an oven that uses two trolleys within a single cooking compartment. Ideal for curing, drying, and baking large or multiple components in manufacturing and surface treatment industries.

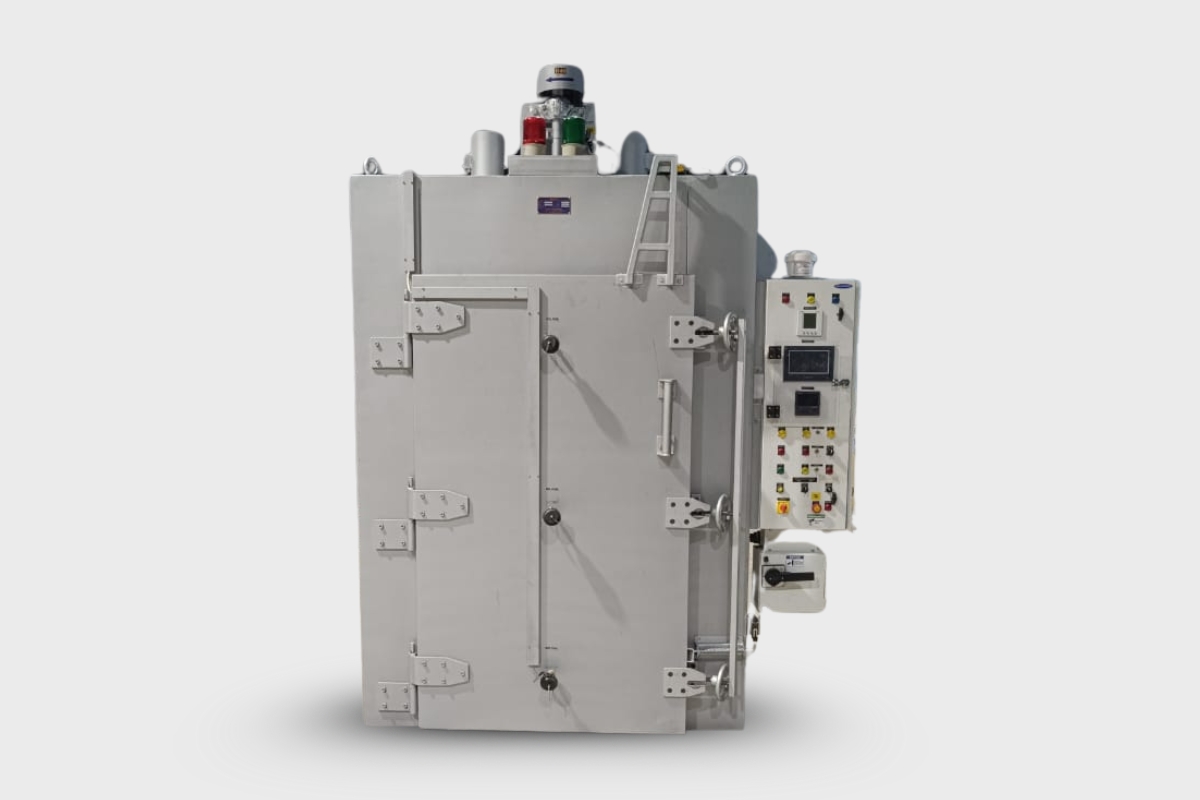

Electrically Heated Trolley-Type Oven

An electrically heated trolley-type oven is an industrial oven that uses electric heating elements and incorporates a trolley or rack system for loading and unloading large quantities of materials or products. They are commonly used in uniform heating, drying, and curing.

HOT AIR OVEN With Different Capacities

A hot air oven is a laboratory equipment designed for dry heat sterilization, drying, and thermal testing. It operates through forced convection, circulating hot air uniformly within an insulated chamber to ensure even heating of samples.