Environmental Test Chambers for Simulated Testing

Environmental Test Chambers

Key Features

Wide-Range Climate Simulation

Achieve testing accuracy across extreme conditions, with temperature capabilities from -70°C to +180°C

Advanced PLC-Based Control System

User-friendly touchscreen interface with programmable logic controller for seamless operation and real-time monitoring.

Stainless Steel Inner Chamber

Corrosion-resistant, hygienic, and durable for long-term testing performance.

Uniform Air Circulation

Equipped with dynamic airflow systems for consistent temperature and humidity distribution.

Comprehensive Safety Integration

Features include auto-cutoff systems, overheat protection, door status sensors, and audible/visual alarms

Applications

Programmed Circuit Board Validation

Pharmaceutical Stability Testing

Aerospace & Defense Test Materials

Plastic & Polymer Research

Telecom Equipment Testing

Primary Benefits

Test with Confidence

Regulatory Compliance

Custom Engineering

Operational Efficiency

Data Integrity

Technical Specifications

| MODEL | S Env TC – 1 | S Env TC – 2 | S Env TC – 3 |

|---|---|---|---|

| CHAMBER SIZE – L x W x H cm | 45 x 50 x 65 | 60 x 60 x 60 | 90 x 90 x 90 |

| No of Shelves | 2 | 3 | 3 |

| Construction | Double walled chamber | ||

| MATERIAL Outer | Mild steel sheet finished with powder coating | ||

| Inner chamber | Stainless Steel | ||

| Air circulation/Motor HP | Forced Air Circulation | ||

| Heater kw | 2.5 | 4.5 | 6 |

| Working Temperature range °C | 40 to 150° C | ||

| Temperature controller | Microprocessor based programmable controller | ||

| Temperature accuracy | ± 0.5° C | ||

| Relative humidity range | 60 % to 90% ± 2% accuracy | ||

| INSULATION | 50 mm thick PUF thermal resistance | ||

| Power Source | AC 220 V 50/60 Hz single phase | ||

Why Choose Servo Enterprises for Environmental Test Chambers?

Our Products

Salt Spray Chambers

Salt Spray Chambers simulate corrosive environments using a controlled salt mist to evaluate the rust resistance of coatings, metals, and surface treatments. Ideal for accelerated corrosion testing in automotive, marine, and industrial applications.

Thermal Chamber

Thermal Chambers create precise high and low-temperature conditions to test material durability, performance, and thermal cycling behavior. Widely used in electronics, aerospace, and industrial product validation processes.

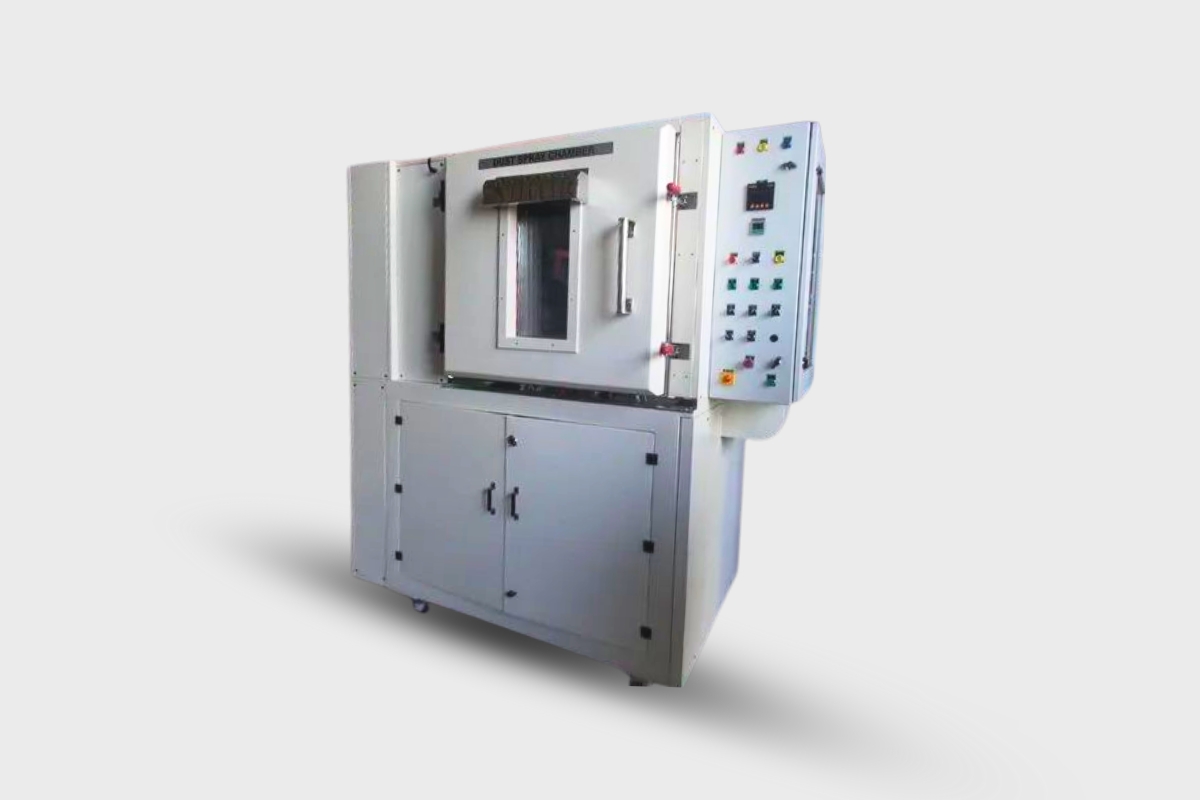

Dust Chambers

Dust Chambers replicate dusty environments to evaluate the ingress protection (IP) of electrical and mechanical devices. Suitable for automotive, defense, and industrial component testing against particulate intrusion.

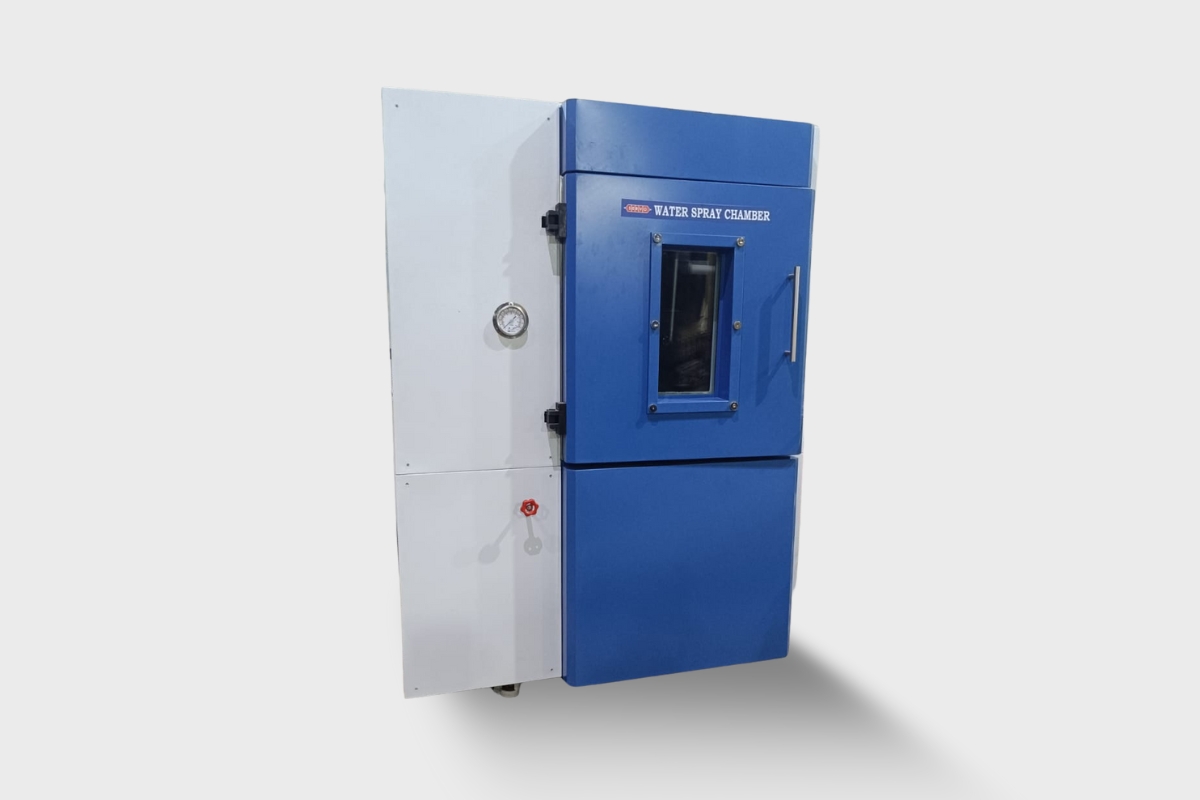

Water Spray Chamber

Water Spray Chambers test the water resistance of products by simulating rain, splash, and hose-down conditions. Ideal for validating enclosures, automotive parts, and outdoor equipment against water ingress.

Humidity Chamber

Humidity Chambers maintain stable temperature and humidity conditions to test material expansion, condensation resistance, and long-term product reliability. Commonly used in electronics, pharmaceuticals, and packaging industries.

CCT

CCT Chambers combine salt spray, drying, and humidity cycles to simulate real-world corrosion conditions. Essential for advanced automotive and industrial coatings testing under varying environmental stresses.

Rain Test Chamber

Rain Test Chambers simulate heavy rainfall and water spray to evaluate waterproofing and enclosure protection. Used in testing electronics, lighting, automotive exteriors, and outdoor appliances.

Deep Freezer

Deep Freezers provide ultra-low temperature storage and testing down to -40°C, ensuring stable conditions for biological samples, chemicals, and temperature-sensitive materials in labs and manufacturing.

Ultra Deep Freezer

Ultra Deep Freezers reach temperatures as low as -80°C, ideal for long-term storage of vaccines, pharmaceuticals, enzymes, and research materials requiring extreme cold preservation.

Dehumidifier

Dehumidifiers remove excess moisture from air to control humidity levels in labs, cleanrooms, and production areas. Crucial for preventing mold, corrosion, and moisture-related product damage.